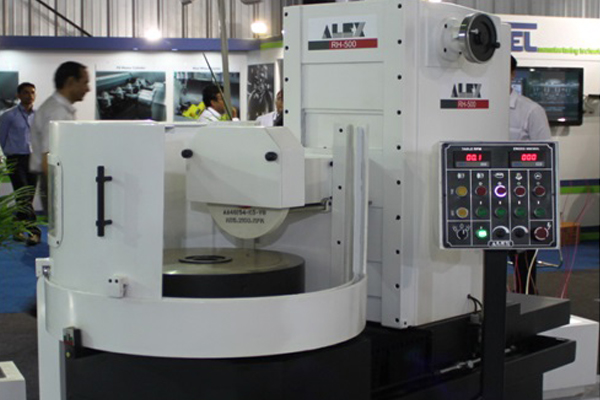

Modern Rotary Surface Grinding Machines come equipped with a variety of advanced features that enhance performance, precision, and ease of operation. Below are some of the most innovative features:

1. CNC Control Systems

Advanced CNC (Computer Numerical Control) systems allow for precise programming of grinding parameters, reducing manual intervention and improving repeatability across production runs.

2. High-Precision Spindle Technology

New-generation spindles offer variable speed control and superior stability, which ensures high-quality surface finishes even under heavy-duty operations.

3. Automatic Wheel Balancing

Integrated automatic balancing systems extend wheel life and ensure uniform grinding performance by reducing vibrations during operation.

4. Real-Time Monitoring & Diagnostics

Sensors and smart monitoring tools track machine performance in real time, providing alerts for maintenance and helping to prevent unexpected downtime.

5. Advanced Cooling and Lubrication Systems

Enhanced coolant delivery systems manage heat build-up efficiently, protecting both the workpiece and the machine from thermal distortion.

6. Touchscreen User Interfaces

Modern Rotary Surface Grinding Machines feature intuitive touchscreen interfaces, making operation simpler and reducing the learning curve for new users.

7. Automated Load/Unload Systems

Some models offer robotic arms or pallet systems for automatic material handling, increasing throughput and reducing manual labor.

With these cutting-edge features, a Rotary Surface Grinding Machine can deliver unmatched precision and reliability, making it a vital asset in high-performance machining environments.

Read More: Evolution of Surface Grinding Machine: From Manual to CNC

Comments