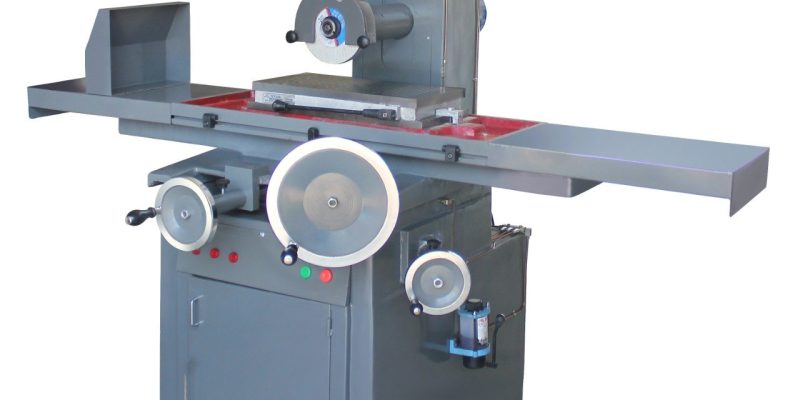

In high-precision industries, even the smallest imperfection can lead to costly delays or product failure. That’s why manufacturers and metalworkers rely on the surface grinder machine—a tool engineered to deliver outstanding flatness, fine finishes, and exact dimensions.

What Is a Surface Grinder Machine?

A surface grinder machine is a mechanical tool used to smooth and refine the surface of a material—typically metal—by removing microscopic layers using an abrasive grinding wheel. It creates a level, mirror-like surface that meets extremely tight tolerances, often within a few microns.

Available in both manual and CNC-controlled versions, surface grinders are widely used in tool and die making, precision engineering, and custom fabrication.

Why Choose a Surface Grinder Machine?

Unmatched Accuracy

Surface grinders allow for precision down to the micron level. Whether you’re grinding flat stock, sharpening a cutting tool, or fine-tuning a component, a surface grinder machine ensures accuracy you simply can’t achieve with hand tools or standard milling equipment.

Superior Surface Finish

The grinding wheel on a surface grinder machine is specifically designed to leave a flawless finish. This smooth surface not only improves aesthetics but also enhances the part’s function—reducing friction, improving mating surfaces, and extending the lifespan of the final product.

Material Versatility

From hardened steel and stainless to aluminum, brass, and even composites—a surface grinder machine can handle a wide range of materials, making it an indispensable asset across industries.

Efficiency and Repeatability

Once setup is complete, surface grinders offer high repeatability, making them ideal for both prototyping and mass production. Automated versions further reduce operator involvement, cutting down on labor costs while boosting throughput.

Applications of Surface Grinder Machines

A surface grinder machine finds its use in multiple applications, including:

- Tool and die maintenance

- Fixture flatness and squareness

- Mold component finishing

- Machine part refurbishment

- Surface preparation before coating or bonding

Its ability to achieve micron-level tolerance ensures that the final product consistently meets high-performance standards.

Boost Your Workflow with Precision Grinding

Investing in a surface grinder machine means more than just acquiring a tool—it means committing to quality, precision, and competitive advantage. Whether you operate a small workshop or a large-scale industrial plant, the benefits of surface grinding are clear:

- Lower rejection rates

- Better fitting parts

- Improved surface contact

- Enhanced mechanical performance

Conclusion

If you’re serious about quality and precision, it’s time to unlock the full potential of your workshop with a surface grinder machine. Its ability to produce accurate, repeatable, and high-quality finishes makes it a cornerstone of modern machining.

Comments